At the end of their training, holders of the Industrial Maintenance Technician Vocational Qualification will be able to carry out all the technical, administrative and management actions designed to maintain an asset or restore it so that it can perform its required function during its life cycle.

He will thus be able to:

- perform technical interventions on multi-technology industrial installations in an operating context by carrying out preventive maintenance operations aimed at preventing the occurrence of a fault, corrective maintenance operations aimed at restoring the initial functioning of a faulty machine and predictive maintenance (or predictive) operations consisting of analysing the operating parameters of an installation with the aim of detecting drifts and anomalies.

- organise and manage maintenance to ensure that it is implemented and monitored in line with the company's strategy.

- suggest technical and organisational improvements and seek performance gains: identify, study and implement projects to improve the reliability, maintainability, availability and safety of assets.

- work effectively as part of a team and in collaboration with the production department, but also with the design office, methods office and purchasing departments.Certificate of professional competence 1: Perform maintenance on electromechanical and automation elements of industrial installations

- Perform preventive, corrective and predictive maintenance on electromechanical and pneumatic elements.

- Perform preventive, corrective and predictive maintenance on automation and servo-control elements.

Certificate of professional competence 2: Perform maintenance on mechanical and hydraulic elements of industrial installations

- Perform preventive, corrective and predictive maintenance on mechanical elements.

- Perform preventive, corrective and predictive maintenance on hydraulic components.

Certificate of professional competence 3: Organising and managing the maintenance of industrial installations

- Designing a maintenance plan and formalising the associated documents

- Leading a team and organising the implementation of maintenance work

- Filling in and using a computer-assisted maintenance management software package (CMMS)

Certificate of professional skills 4: Study and carry out an improvement maintenance project

- Study and design an improvement maintenance project

- Organise and implement an improvement maintenance project.Find out more about this qualification (RNCP36247, exact wording of the diploma, name of the certifier, registration date of the qualification) by clicking here.

Technological baccalaureate or vocational baccalaureate in the field of the Vocational Qualification speciality

8

Positioning upstream of training entry.

Interviews, remediation with the educational referent and/or company referent during training.

Taking into account beneficiary satisfaction during and at the end of training.

Possibility of post-training support.

Education Nationale certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers.

Tests at the end of training (one-off assessment)

Course evaluations (ECF)

Professional portfolio

Interview with a professional jury

Positioning test by appointment.

Show up with the liaison form from the prescriber (Mission locale, Pôle emploi...).

Interview by appointment.

Insertion into employment in positions as:

- Industrial maintenance technician

- Maintenance technician for production/manufacturing equipment, electrotechnician/electromechanical technician/mechanical maintenance technician/automation technician.

- Maintenance methods technician, industrial maintenance manager or team leader

Access for people with disabilities

Accessible to people with disabilitiesTransport

Success rate: 90%

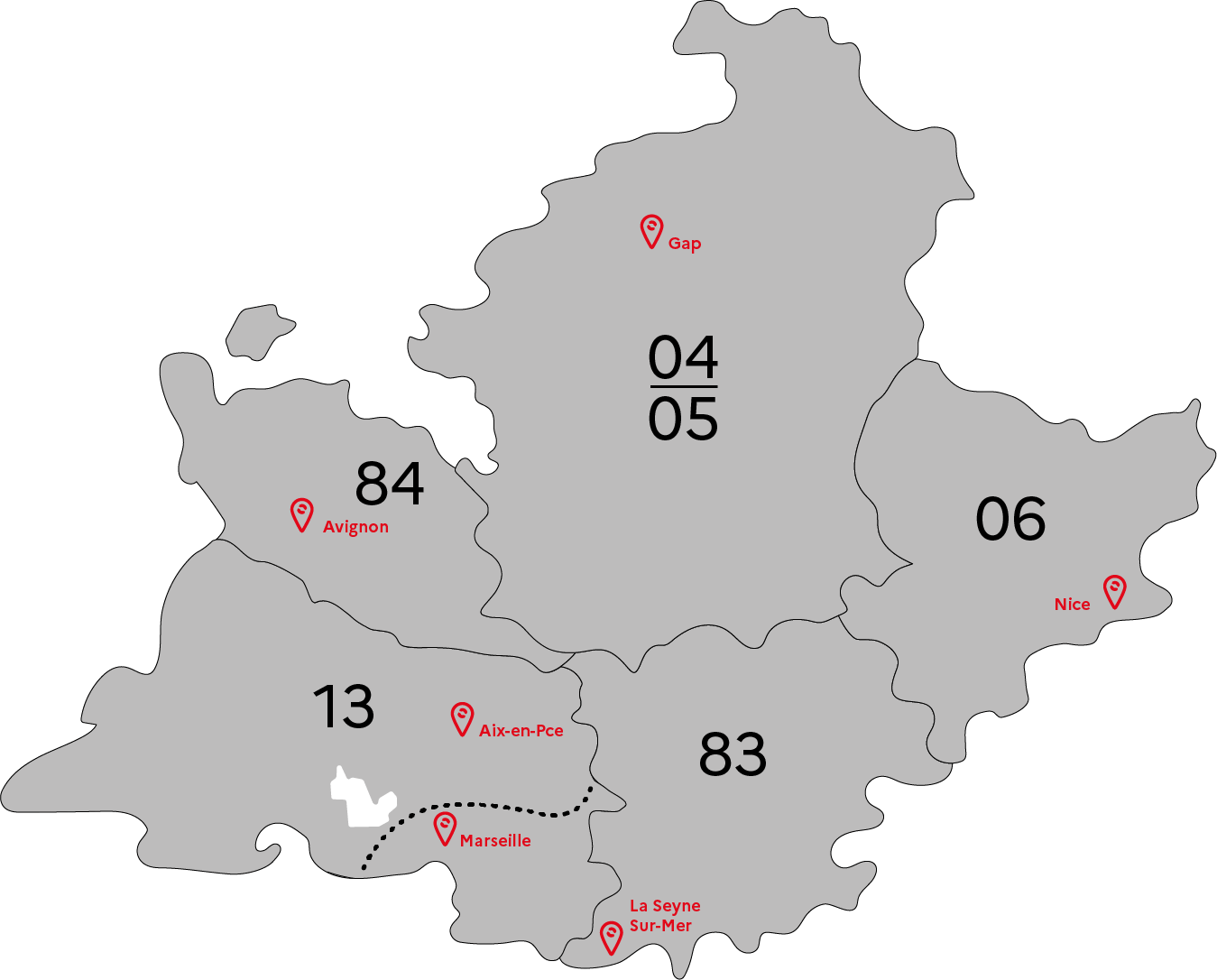

GRETA-CFA Provence

GRETA-CFA Provence

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS