At the end of the training, you will be able to:

- determine manufacturing processes on your own or with the methods office depending on the company's configuration,

- prepare productions, carry out machining programmes on a computer-assisted manufacturing system or on the NCM console,

- set up NCMs to produce unit parts or small series to be developed before entrusting them to a machining operator,

- put in place all the resources needed to enable the operator to carry out series production in compliance with the requirements of the definition plan

- intervene with operators to resolve incidents beyond your scope of intervention.

In collaboration with the machining operators you may be required to supervise, the maintenance and quality methods department, you will:

- monitor production and quality indicators and may propose improvement solutions if necessary.

- may, depending on the configuration of the companies, be required to run production runs yourself that you have prepared and set up.

- intervene in routine maintenance and simple troubleshooting of resources useful in production.

- work in accordance with the health, safety and environmental standards in force in the company.

- guarantee compliance with safety instructions for accident prevention and the wearing of personal protective equipment.

- collaborate with the various departments, methods, quality and maintenance.

- mostly work standing up in front of the machine or machines in the fleet, sometimes sitting down during the preparation phases carried out on a computer-aided manufacturing system.

Depending on the organisation and type of production, the work may be shift or day work. The work carried out by the machining technician takes place in a clean and tidy environment. The machines are equipped with innovative digital technologies. To make it easier to use CNC controllers, the new generation of digital interfaces has a touch screen with 3-dimensional image definition. Machining technicians frequently use IT resources, particularly for production monitoring and programme management.

>.

Module 0 - Welcome, presentation of training objectives, knowledge of the professional environment, adaptation of the training path

Module 1 - Carry out, from a drawing, the machining of unit parts or small series on a numerically controlled lathe:

- Schedule machining operations and programme machining on a numerically controlled lathe.

- Carry out machining of unit parts or small series on a numerically controlled lathe.

- Ensure the control and traceability of a production of machined parts

Module 2 - Carry out, from a drawing, the machining of individual parts or small series on a machining centre

- Schedule machining operations and programme machining on a machining centre

- Carry out the machining of individual parts or small series on a machining centre

- Ensure the control and traceability of a production of machined parts

Module 3 - Prepare and set up series machining productions on machine-numerically controlled machine tools -

- Prepare for the production of new parts on a computer-aided manufacturing system

- Organise and prepare the workstation for the production of new series of parts

- Stabilise and launch series machining production on numerically controlled machine tools

Transversal modules - Refresher, personalised support, job search techniques

Certification and job dating module - preparation, exams and job dating - Trainees are supported in their search for a work placement

Follow-up at the work placement is carried out by the trainer

Find out more about this qualification (RNCP35182, exact wording of the diploma, name of the certifier, registration date of the qualification) by clicking here.

Anybody

Good physical condition, experience or diploma in the industry sector, proficiency in reading blueprints preferred.

8 people

Positioning upstream of entry to the training course.

Interviews, remediation with the educational referent and/or company referent during the course.

Taking account of beneficiary satisfaction during and at the end of the training course.

For beneficiaries with disabilities: possible adaptation of training and certification arrangements, support by the GRETA-CFA TH referent.

Education Nationale certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers.

Tests at the end of training (One-off assessment)

Interview with a professional panel

Possibility of validating one or more blocks of skills

In the event of partial validation of the certification, the modules obtained are valid for : 5 years.

Positioning test and interview by appointment.

Present yourself with the liaison form from the prescriber (Mission locale, Pôle emploi...).

On completion of the course, you can take up the following positions:

- Mechanical production unit manager

- Mechanical production unit manager

- Mechanical elementary production unit manager

- Mechanical manufacturing production technician

- Workshop technician

The various sectors of activity concerned are mainly: automotive, aeronautical, armaments, rail, agricultural machinery, boating, optics, petrochemicals, transport, electricity, household appliances, sport and leisure.

The aim of the vocational qualification is professional integration but, with a good record, further study is possible in a BTS.

Access for people with disabilities

Accessible to people with disabilities

(Rate calculated on those leaving the course)

* Reference period 01/09/2022 to 30/07/2023, calculated on the number of responses obtained

GRETA CFA Vaucluse | Avignon | Facebook

GRETA-CFA Vaucluse (@gretacfa.vaucluse) - Instagram photos and videos

GRETA-CFA Vaucluse | LinkedIn

GRETA-CFA VAUCLUSE - YouTube

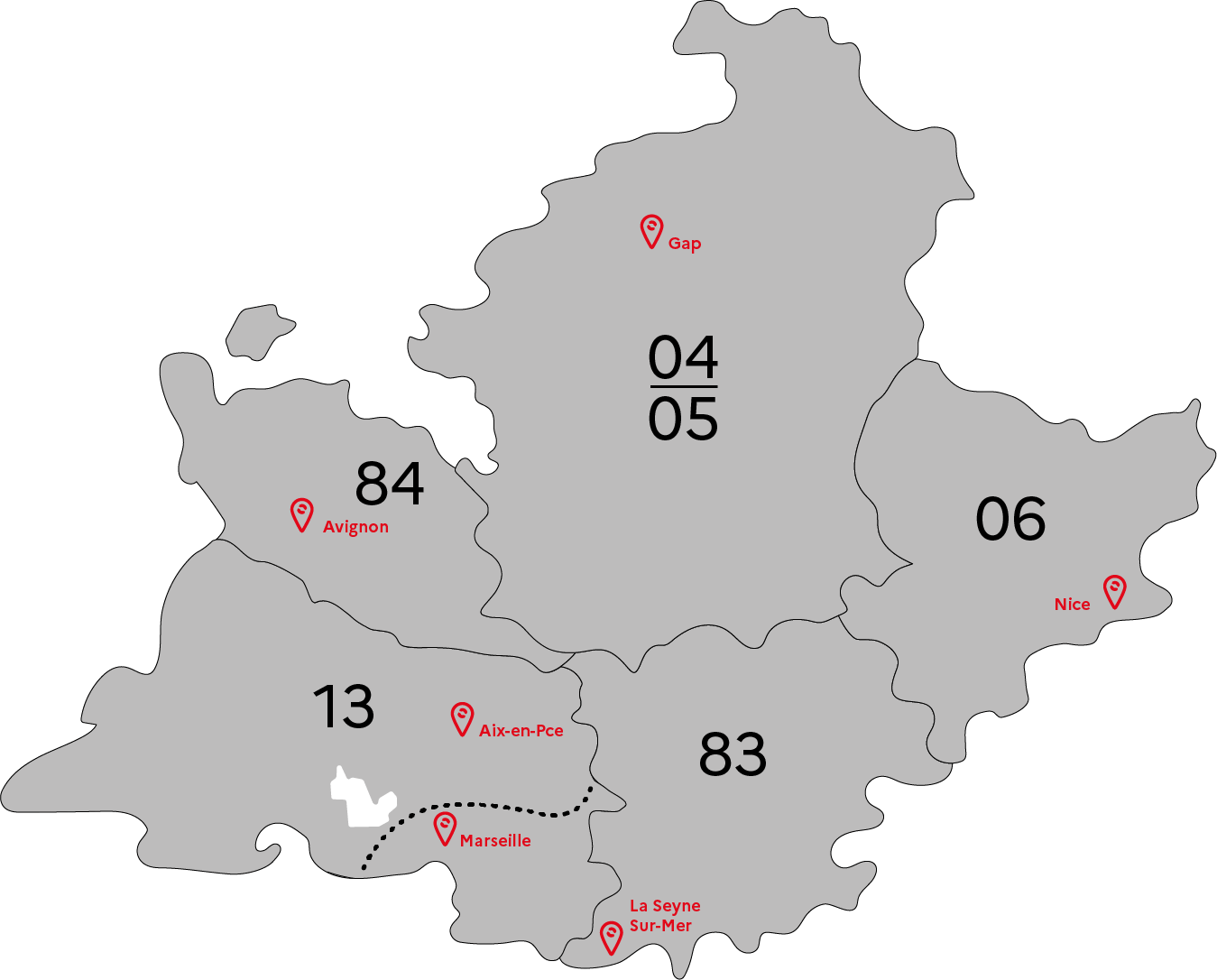

GRETA-CFA Vaucluse

GRETA-CFA Vaucluse

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS