Boilermaking technicians carry out and manage operations to transform metals into sheets, tubes and profiles.

Reporting to a line manager, they work from a file containing plans, diagrams and instructions to manufacture standard and complex structures intended for multiple sectors of activity. They work autonomously on all manufacturing operations, from preparation to conformity checking, including cutting, shaping and assembly by welding. They work on both traditional manually-operated and numerically-controlled machines, complying with the precision required by the technical file, as well as quality and health and safety regulations. They complete the manufacturing files sent to them using digital tools.

The boilermaking technician works alone or as part of a team, depending on the organisation of the work and the size of the company.

In the workshop, he/she works in a standing position and in an often noisy environment. They may be required to travel to worksites to prepare and organise a job, carry out a maintenance operation or modify equipment.

The Boilermaking Technician vocational qualification consists of 3 Certificates of Professional Competence (CCP):

Certificate of Professional Competence (CCP) - 1 : Manufacture standard boilerwork assemblies

Certificate of professional skills (CCP) - 2. Manufacturing a complex boilerwork assembly

Certificate of professional competence (CCP) - 3. Follow the stages in the manufacture of a boilerwork assembly

Domains studied to obtain these 3 CCP:

Plan reading, Tracing, Work preparation, Practical boilermaking, , Assembly, Maintenance, Industrial organisation, Safety, Methods and problem solving, Production management and organisation, Techniques for finding work experience/jobs

Find out more about this qualification (RNCP34858, exact wording of the diploma, name of the certifier, registration date of the qualification) by clicking here.

Level 3ème or equivalent experience.

In arithmetic, mastery of the 4 operations, conversions, fractions and proportionality (rule of 3); in geometry, mastery of area and volume calculations.

10 people

Positioning upstream of entry to the training course.

Interviews, remediation with the educational referent and/or company referent during the course.

Taking account of beneficiary satisfaction during and at the end of the training course.

For beneficiaries with disabilities: possible adaptation of training and certification arrangements, support by the GRETA-CFA TH referent.

Education Nationale certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers.

Tests at the end of the course (one-off assessment)

Interview with a professional jury

Possibility of validating one or more blocks of skills

In the event of partial validation of the certification, the modules obtained are valid for:5 years

.Positioning test by appointment.

Interview by appointment.

Present yourself with the liaison form from the prescriber (Mission locale, Pôle emploi...).

Access the following trades:Boilermaker plan assembler, boilermaker, Boilermaker Welder, Boilermaker metalworker, boilermaker sheet metal worker

Exercise in companies manufacturing machinery and equipment, furniture, automotive industry and transport equipmentContinue your studies in :CQPM Product or mechanical systems designer in a design office (BTS level),Mention Complémentaire Technicien en chaudronnerie aéronautique et spatiale,BTS Conception et Réalisation en Chaudronnerie Industrielle (if very good level)

Access for people with disabilities

Accessible to people with disabilitiesTransport

1st session

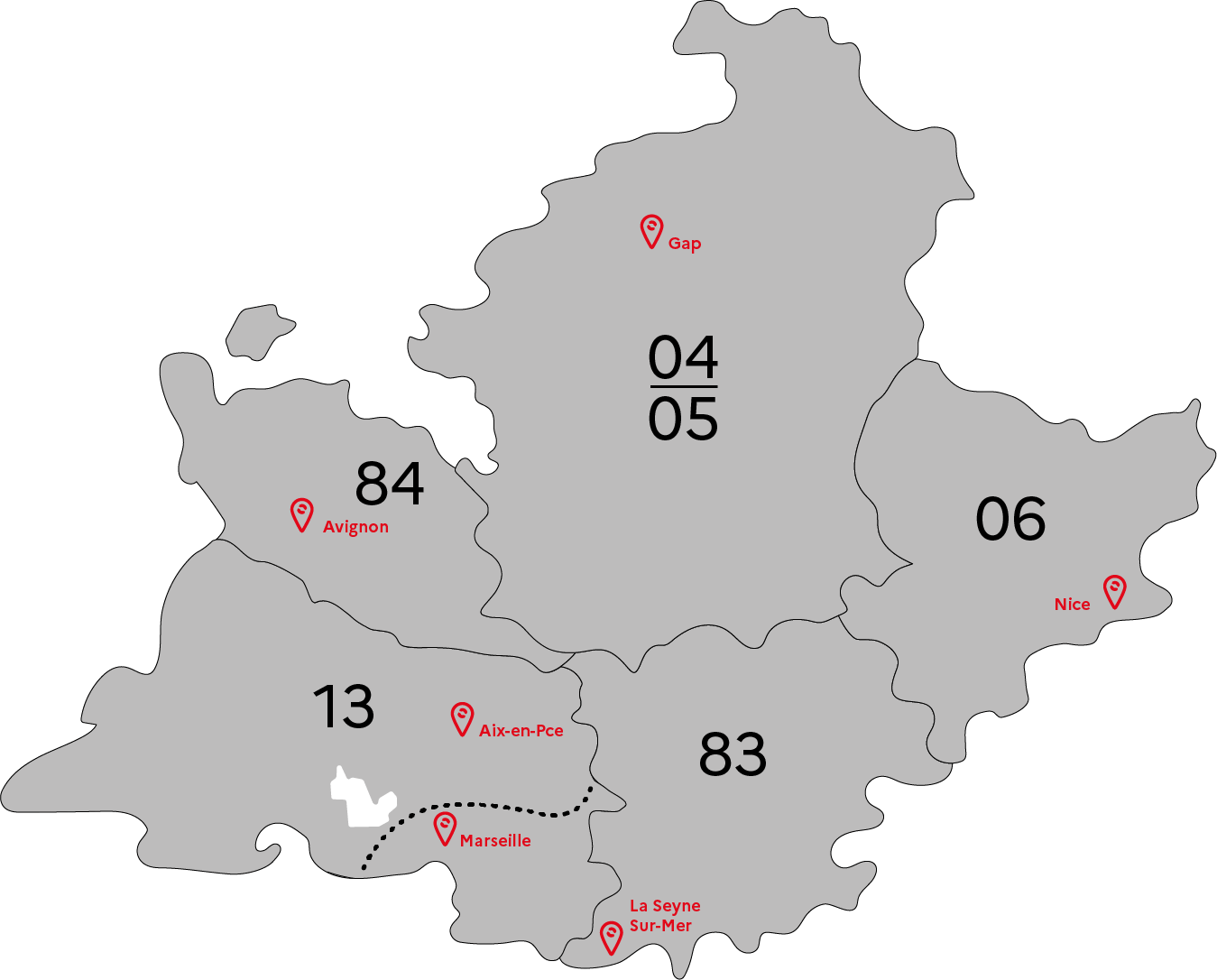

GRETA-CFA Provence

GRETA-CFA Provence

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS