The objectives will be specified according to your production requirements:

.

TECHNOLOGICAL TRAINING: History, principle and field of use of the process; Diagram and description of installations with and without gas (INNERSHIELD);

Equipment: Generators, Reels, torches and guns; Flux roles and wire manufacture; Gases used in flux-cored wire welding; Welding parameters, choice, influence and interdependence: Voltage, current, welding speed; Length of wire output (STICK-OUT); Weld defects; Means of control, health and safety

PRATICAL TRAINING: Making weld beads on different types of joints: Internal, external angle, overlap, butt, straight, V and X chamfered edges; Welding positions: Flat, rising, cornice and ceiling; Checking assemblies using textures and X-rays

Ongoing assessment by the trainer of the practical exercises carried out by the participant: analysis of the quality of the assemblies (visual inspection of welds, macroscopies, bending) and corrective action.

Personalised and individualised training.

Commented practical demonstrations.

Technological presentations illustrated by audiovisual means.

No pre-requisites required.

EN-certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers

This course is aimed at welders, metalworkers, boilermakers, bodybuilders and maintenance staff who wish to learn, improve or specialise in flux-cored wire welding.

Access for people with disabilities

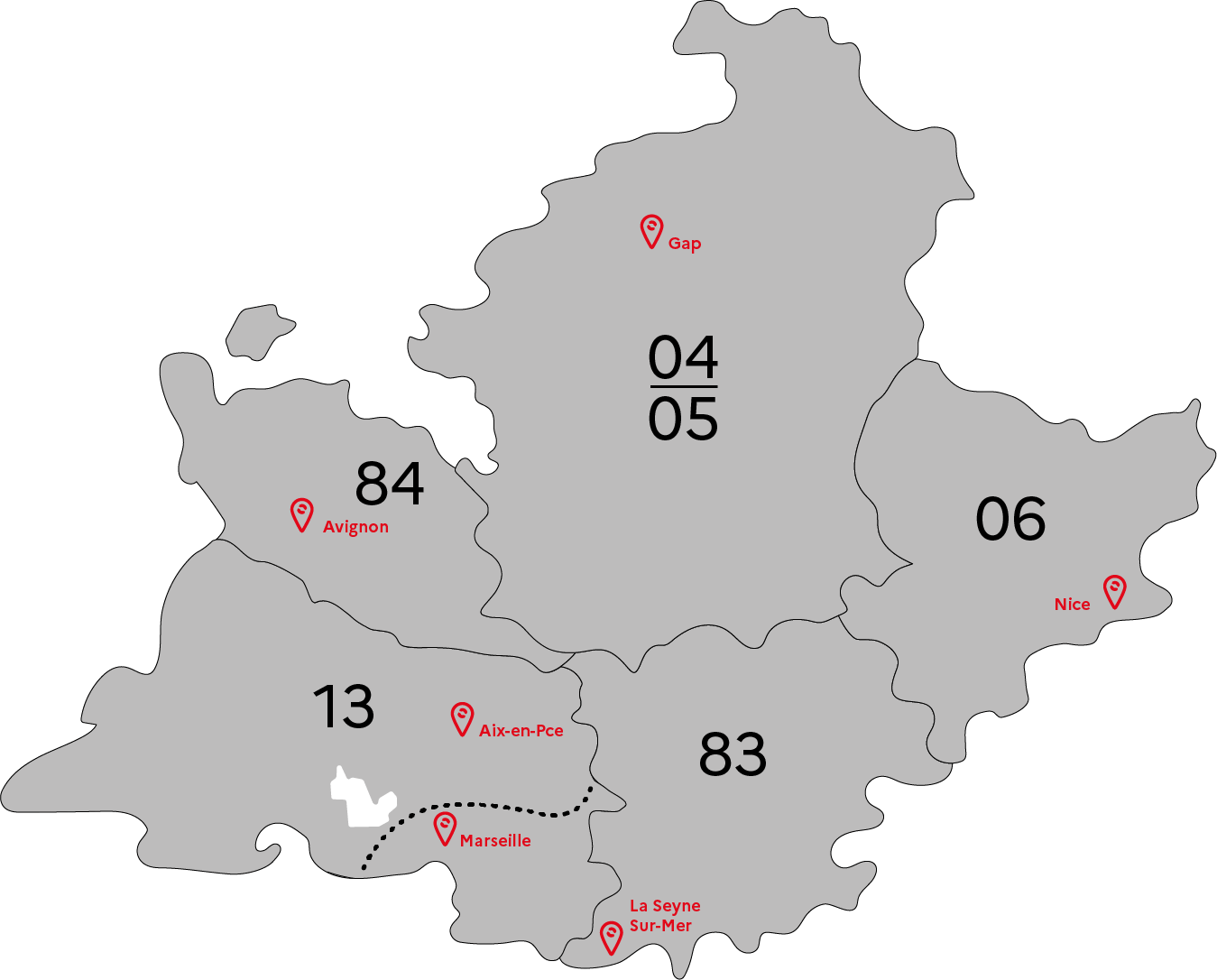

Accessible to people with disabilitiesGRETA-CFA Vaucluse

GRETA-CFA Vaucluse

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS