The objectives will be specified according to your production requirements:

.

Based on the participants' prior learning and the training objectives, each person will progress at his or her own pace in the following educational progression:

TECHNOLOGICAL TRAINING: History, principle and field of use of the process; Equipment and products; Cutting and welding torches; Filler metals; Gases used; Torch settings; Edge preparation; Welding methods; Operative weldability; Weld defects; Means of control; Health and safety.

PRATICAL TRAINING: Welding beads on different types of joints; Welding sheet metal in position; Welding sections; Welding tubes in rotation, ledge and rising; Welding tappings; Checking assemblies by bending and X-rays

Ongoing assessment by the trainer of the practical exercises carried out by the participant: Analysis of assembly quality (visual inspection of welds, macroscopies, bending) and corrective actions.

No pre-requisites required.

10 people

Positioning upstream of training entry.

Interviews, remediation with the educational referent and/or company referent during training.

Taking account of beneficiary satisfaction during and at the end of training.

Possibility of post-training support.

For beneficiaries with disabilities: possible adaptation of training and certification methods, support by the TH referent.

In order to improve the quality of our service, you can send us your suggestions or complaints using the form available on our website.

EN-certified teachers, trainers with 3 years of higher education and significant experience in adult education, professional lecturers

.In-course evaluations (ICE)

.Access for people with disabilities

Accessible to people with disabilitiesTransport

direction sous préfecture

establishment located on the plateau des bolles bordering the pond

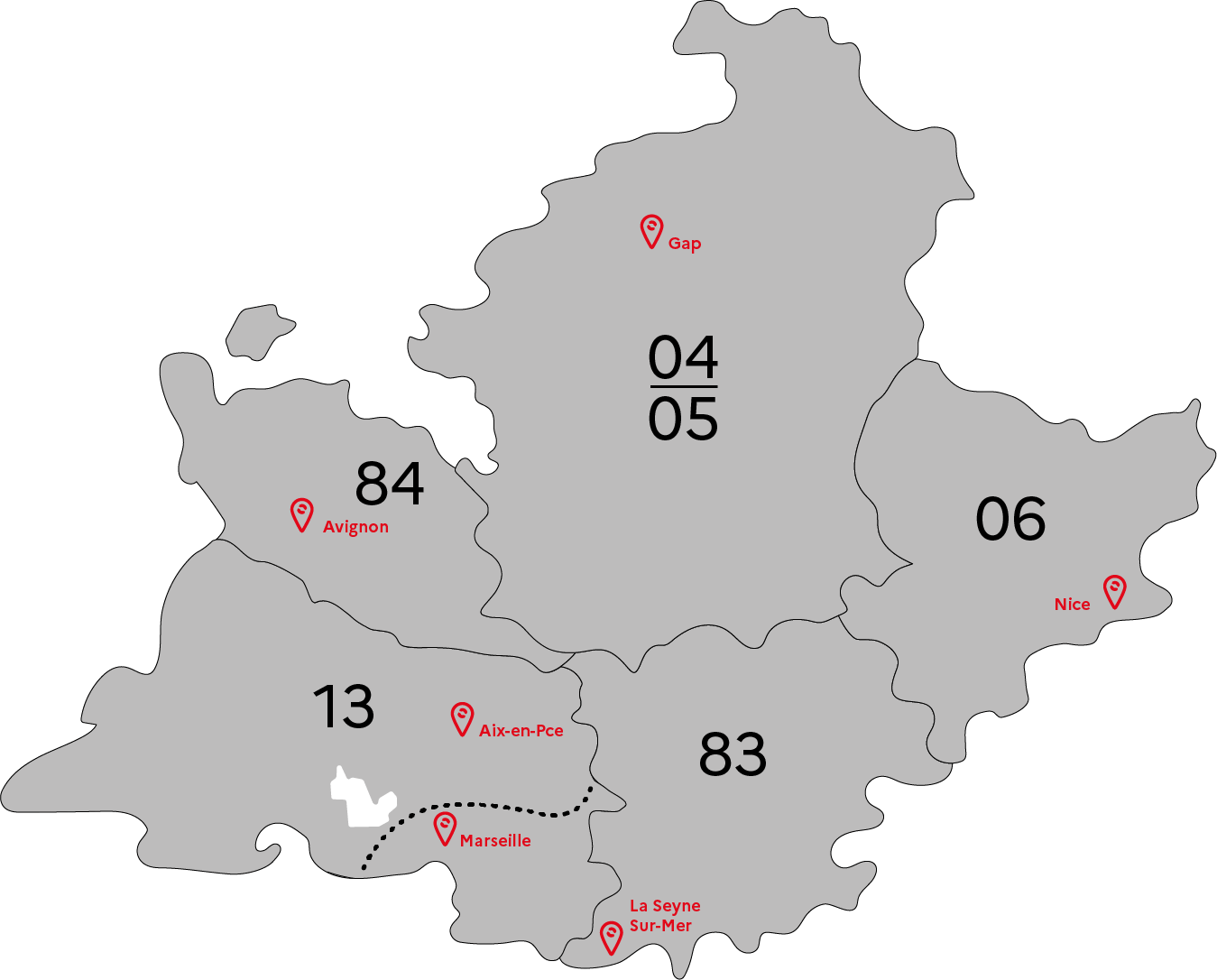

GRETA-CFA Provence

GRETA-CFA Provence

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS