The objectives will be specified according to your production requirements:

Based on the participants' prior knowledge and the training objectives, each person will progress at his or her own pace in the following pedagogical progression:

TECHNOLOGICAL TRAINING: History, principle and application of the process; Type of generators; Equipment used: Wire feeders, contact tube torches, sheaths, rollers, control boxes; Electric arc in MIG MAG welding: Different transfer modes, influence of welding parameters; Gases and gas mixtures used

How to determine for a welded assembly: Wire diameter, transfer mode, current, voltage, wire speed, choke, gas, edge preparation; Weld defects and means of control

Health and safety.

PRATICAL TRAINING: Welding on joint types: Inside corner, outside corner, overlap, butt.

Welding positions: Flat, gutter, downhill, uphill, ceiling and cornice;

Material and thicknesses: Exercises will be carried out on a range of thicknesses from 2 to 10 mm for steels.

Ongoing assessment by the trainer of the practical exercises carried out by the participant: analysis of the quality of the assemblies (visual inspection of welds, macroscopies, bending) and corrective actions.

Personalised and individualised training; Commented practical demonstrations; Technological presentations illustrated by audiovisual means.

No pre-requisites required.

EN-certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers

Access for people with disabilities

Accessible to people with disabilitiesGRETA-CFA Vaucluse

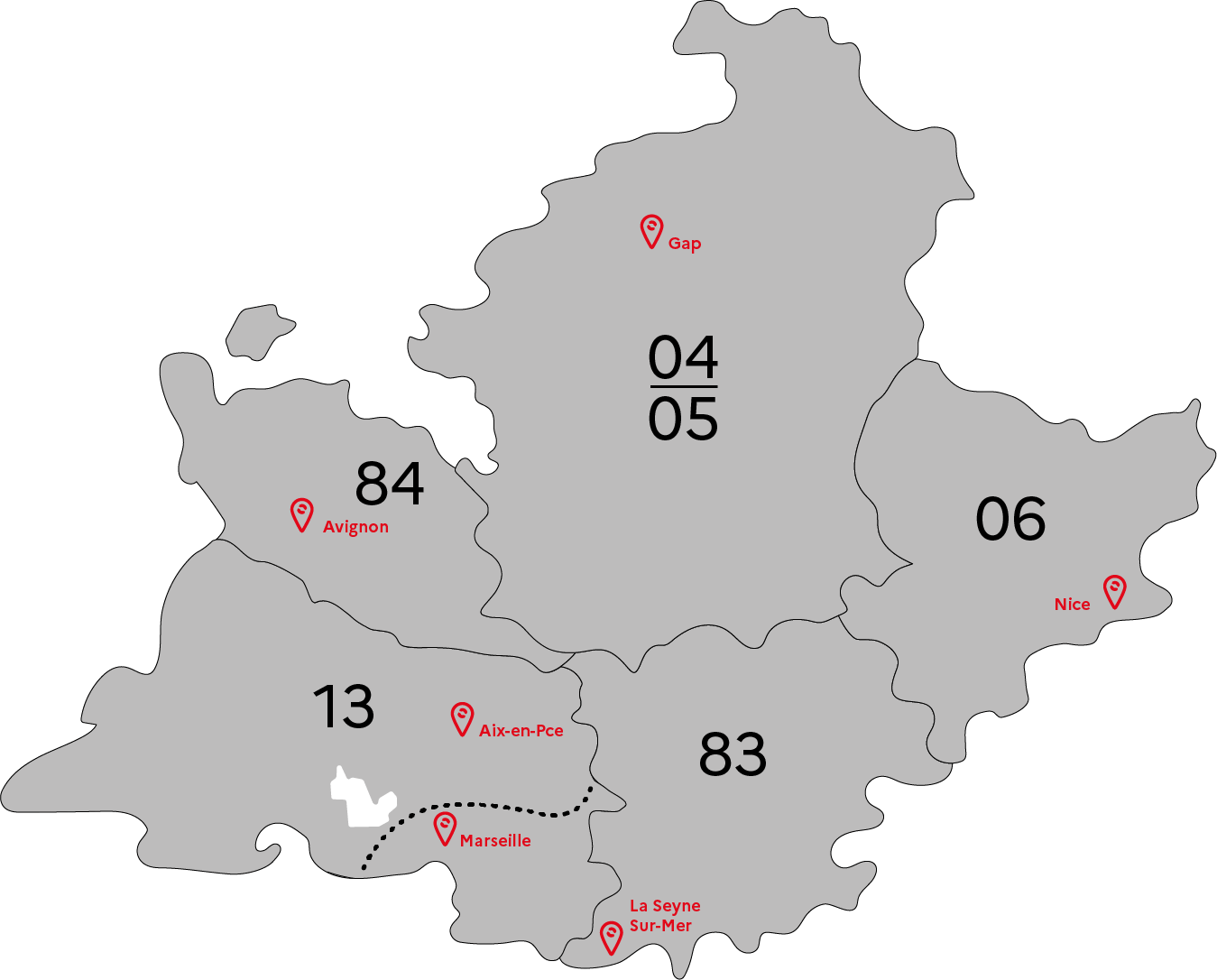

GRETA-CFA Vaucluse

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS