The training is aimed at employees with a level V initial qualification or equivalent experience.

At the end of the training, operators must:

Mechanics: Lubrication, clearances, bearings, plan reading; Mechanical links: rigid and semi-rigid couplings, belt changes; Gearboxes: function and types; Analysis of suspicious noises, abnormal vibrations

Electricity: Power: AC, DC, transformer; The induction motor: operation, dismantling; Equipment, fuses, disconnector, thermal relay, contactors, plan reading, etc..Notions of star-delta starting; Notions of variable speed drives; Sensors, transmitters (CR, Levels, FdC, TOR, Analogue sensors, etc....); Review of examples given by operators

Pneumatics: Notions of force and pressure, compressors, air filtration; Equipment, pre-actuators, actuators, end-effectors, reading drawings, etc.... Dismantling of certain components, forcing

Hydraulics: Notions of pressure and flow, pressurisation components, pressure limiters; Equipment, pre-actuators, actuators, effectors, reading drawings, etc.; Dismantling of certain components, forcing.

Automation: Process diagram: approach to the complete chain. PLC inputs, outputs, general operation; Sensors, transmitters; Possible faults and influences on the system; The PLC: start-up sequence, stop, Notion of simple regulation: open loop, closed loop

A minimum level V qualification from the industrial sector, experience as a production or packaging operator.

Teachers with EN certification or agrégation, trainers with 3 years' higher education and significant experience in adult education, professional lecturers

.Maintenance and positioning

Access for people with disabilities

Accessible to people with disabilitiesTransport

direction sous préfecture

establishment located on the plateau des bolles bordering the pond

GRETA Ouest 13

GRETA Ouest 13

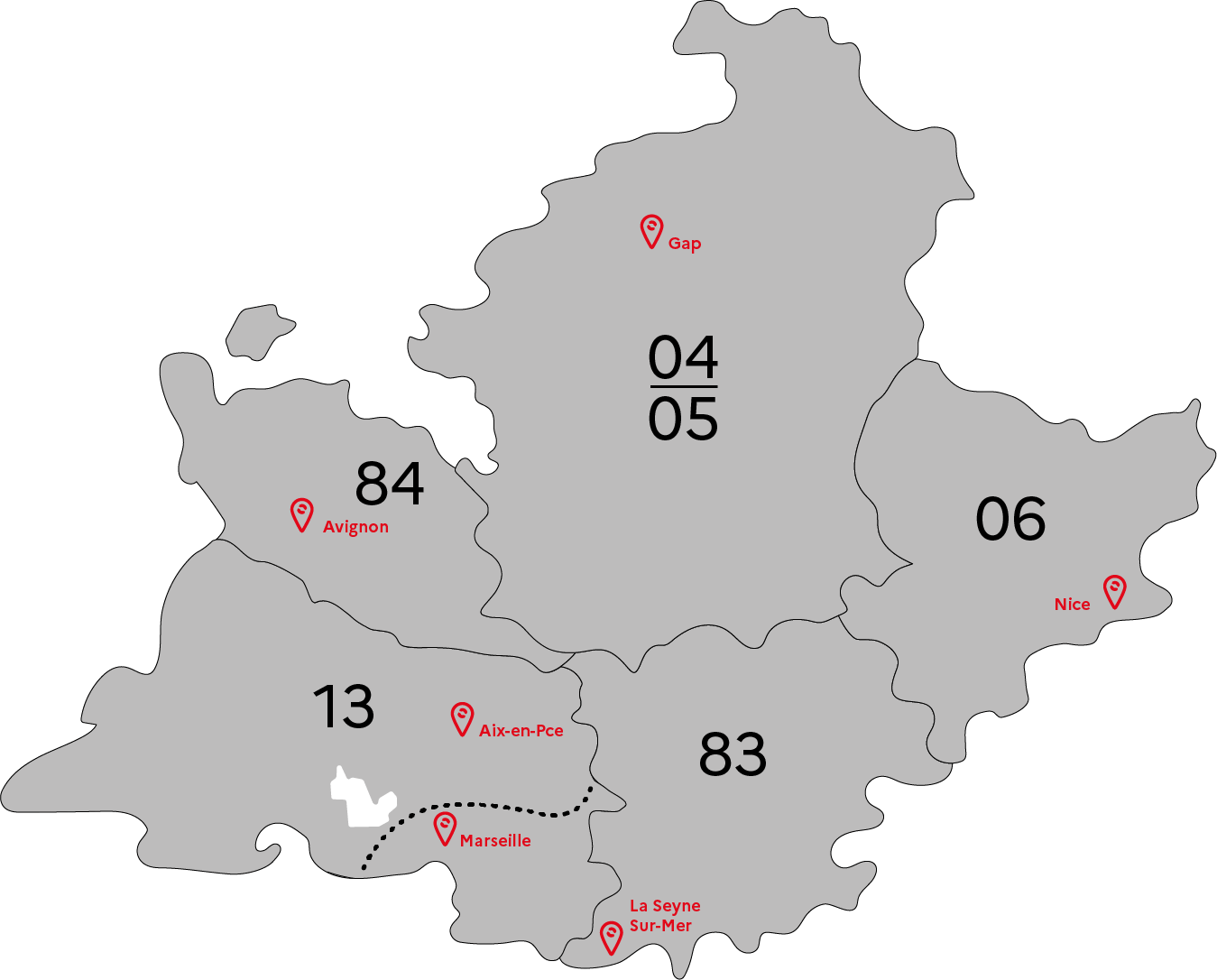

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS