The training is aimed at employees with a level V initial qualification or equivalent experience.

At the end of the training, operators must:

Mechanics: Lubrication, clearances, bearings, plan reading; Mechanical links: rigid and semi-rigid couplings, belt changes; Gearboxes: function and types; Analysis of suspicious noises, abnormal vibrations

Electricity: Power: AC, DC, transformer; The induction motor: operation, dismantling; Equipment, fuses, disconnector, thermal relay, contactors, plan reading, etc..Notions of star-delta starting; Notions of variable speed drives; Sensors, transmitters (CR, Levels, FdC, TOR, Analogue sensors, etc....); Review of examples given by operators

Pneumatics: Notions of force and pressure, compressors, air filtration; Equipment, pre-actuators, actuators, end-effectors, reading drawings, etc.... Dismantling of certain components, forcing

Hydraulics: Notions of pressure and flow, pressurisation components, pressure limiters; Equipment, pre-actuators, actuators, effectors, reading drawings, etc.; Dismantling of certain components, forcing.

Automation: Process diagram: approach to the complete chain. PLC inputs, outputs, general operation; Sensors, transmitters; Possible faults and influences on the system; The PLC: start-up sequence, stop, Notion of simple regulation: open loop, closed loop

A minimum level V qualification from the industrial sector, experience as a production or packaging operator.

Teachers with EN certification or agrégation, trainers with 3 years' higher education and significant experience in adult education, professional lecturers

.Maintenance and positioning

Access for people with disabilities

Accessible to people with disabilitiesGRETA Ouest 13

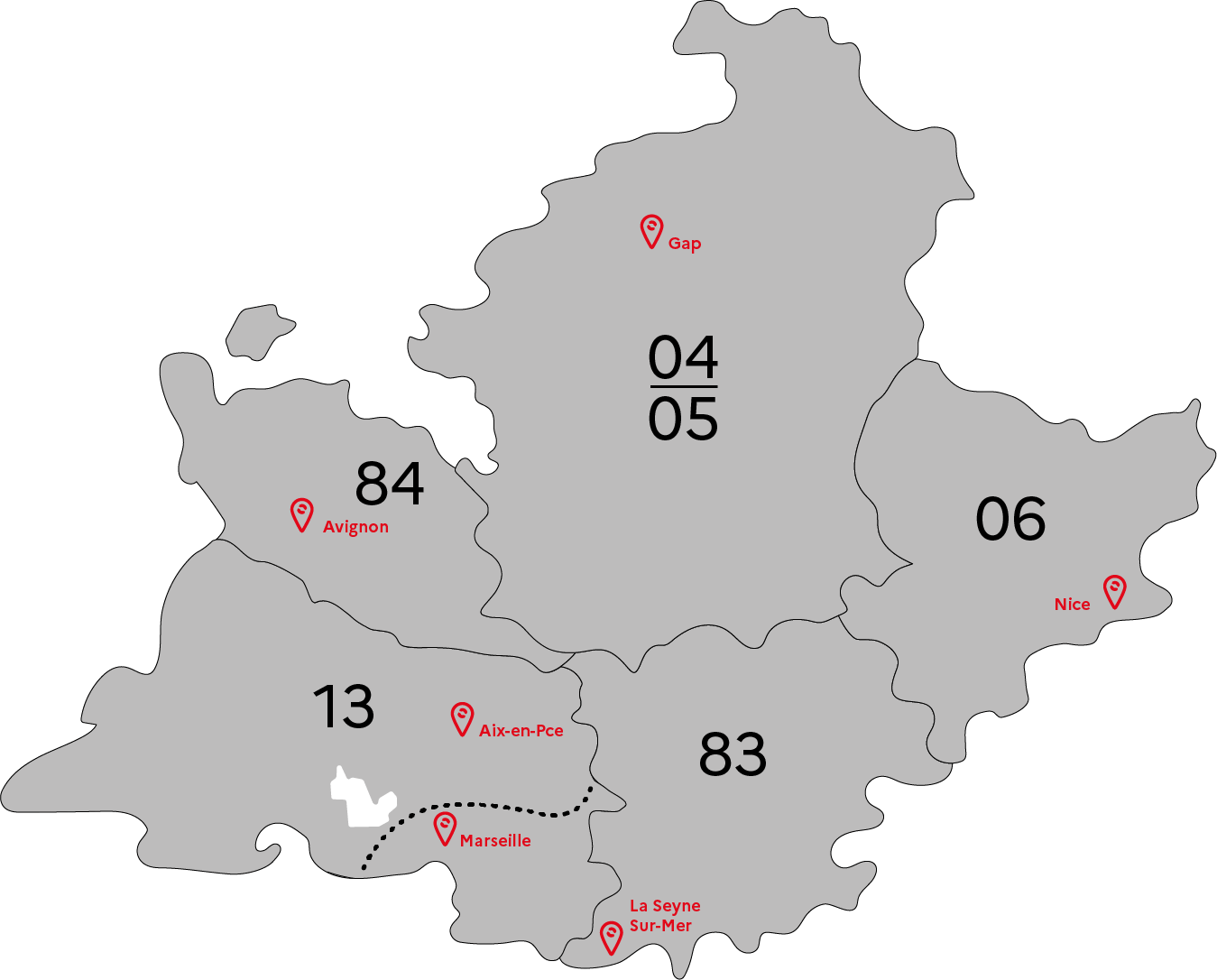

GRETA Ouest 13

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS