- Understanding the constraints of printing processes

- Adapting photogravure to the constraints of flexography

- Adapting the mechanical configuration of the press to the constraints of printability

- Preparing ink according to load and tonality

- Assessing the ecological criteria of processes

- Calculating the break-even point of processes

1 - Photoengraving applied to flexography

2 - Anatomy of a printing unit

3 - Flexo ink

4 - The inking system

5 - Print transfer

6 - Flexo plates and their preparation

7 - Setting up a flexo press

8 - Register setting

9 - Colour setting

10 - Quality control applied to flexo

11 - Advantages and disadvantages compared with offset

12 - Products printed in flexo

13 - Substrates used

14 - Break-even point in flexo

Exercising functions in the graphics chain

EN-certified teachers, Bac +3 trainers with significant experience in adult education, professional lecturers

Maintenance and positioning

Reclaiming your responsibilities as an employee in the graphics industry

Access for people with disabilities

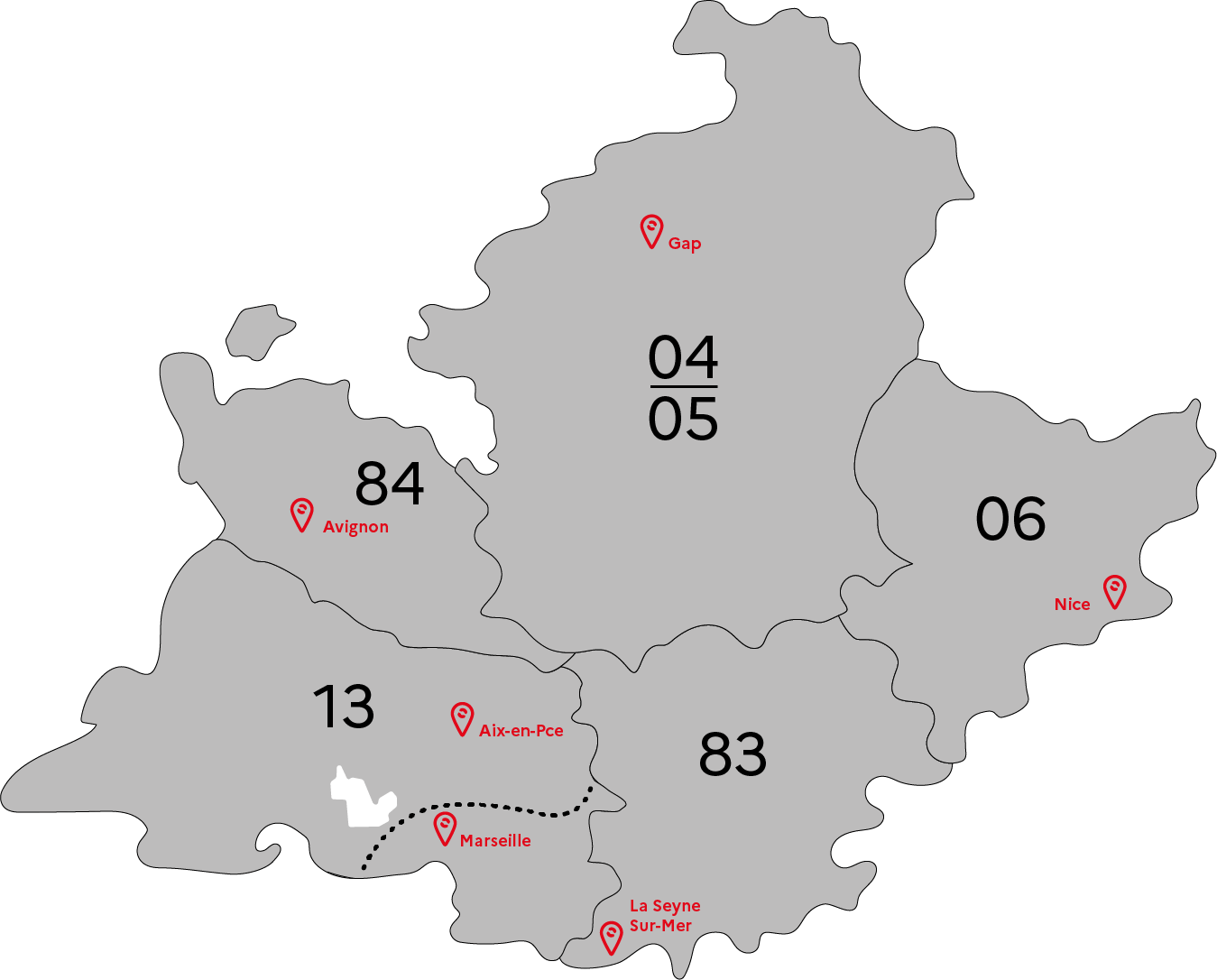

Accessible to people with disabilitiesGRETA-CFA Vaucluse

GRETA-CFA Vaucluse

FORPRO-PACA

Réseau Formation Professionnelle

de l'Éducation nationale

FORPRO-PACA IS HIRING

LINKS